What is PCB solder paste? PCB solder paste is a powdered mixture of flux and solder. It is used to attach thousands of tiny electrical components to their contact pads in the assembly of printed circuit boards. Without it, the process of PCB assembly is incomplete. If you’re looking forward to designing and fabricating a PCB, read this article. It will take you through the crucial points you need to keep in mind while working with solder for PCB.

What Is PCB Solder Paste

In electronics, solder for PCB is a substance used to join two or more components. Similarly, a solder paste has the same function, except that it is used in PCBs instead of the traditional copper boards, and it is in the form of a paste, which gives it some different properties.

Solder paste contains tiny particles of solder dispersed inside a past of solder flux. The paste is a mixture of different metals that is thick in consistency and can be easily applied to the printed circuit board while mounting its components. The flux holds the solder grains together for a smooth flow of current between the electronic components. It used to be a combination of lead and tin, but now manufacturers have started incorporating copper.

Solder Paste types

There are different types of solder pastes available in the market. Solder paste is classified according to the size of particles it has. For example, a type 2 paste has sizeable solder balls than a type 5 paste. As the type number increases, the size of the solder particle decreases.

Here are the solder ball sizes for each type:

| Solder Paste Type | Size of Solder Particle (mm) |

|---|---|

| Type 1 | 75-150 |

| Type 2 | 45-75 |

| Type 3 | 25-45 |

| Type 4 | 20-38 |

| Type 5 | 10-25 |

| Type 6 | 5-15 |

| Type 7 | 2-11 |

| Type 8 | 2-8 |

All the solder particles present in the paste are not of the same size. We consider 80% of the total grains in a paste to fall in the classes mentioned above for our ease. You must be wondering how does the particle size matter while choosing the right paste for your application. The thing is, while working on smaller components, you would want the solder paste to have fine particles so that an even layer of tracks is formed.

If you use a type 3 solder paste to join small components, you might feel that the paths are uneven. Usually, types 3, 4, and 5 are used in electronics.

Another way to differentiate the solder paste is through their flux.

There are three types of fluxes used in solder pastes:

- Rosin – A rosin-based paste, as the name suggests, is made by using rosin. It is a substance obtained from pine trees. You can clean the excess flux using a solvent. It can not be cleaned with water.

- Water-soluble – This type of flux uses organic compounds. As the name indicates, it is water-soluble; hence you can clean it without using an additional solvent.

- No-clean – a no-clean paste, as the name indicates, does not need cleaning. You do not need to invest in other cleaning solvents. People most commonly use this type of flux because of the ease-of-use it offers and the low operating cost.

Choosing a solder paste depends entirely on your application. You can select the size of the solder particle according to the component size and then decide the type of flux you want to invest in. It depends on the user to select the type of solder paste. There are no set guidelines for this purpose.

How To Store

Storing solder paste the right way is essential because it is sensitive to the temperature it’s kept in. You will possibly end up damaging the paste if you store it at the wrong temperature. A deformed solder paste will not adhere to the printed circuit board surface, and unfortunately, you won’t be able to mount your components on the board. So, it’s best to store it in an environment where the temperature is right.

Note: The recommended temperature for storing the paste is between 2℃ to 8℃.

Not complying with the recommended temperature range will result in deformation. Moreover, it would be best if you do not freeze it because doing so will damage the flux, and you won’t be able to use it again. Solder paste is stored at low temperatures to slow down the oxidation process that is harmful. You might be wondering how to keep the paste. Should you put it in a plastic bag or a container?

The answer is simple. You need to make sure that the process of oxidation is slowed down, and for that to happen, you need to keep it away from oxygen. So, the best way to store your solder paste is inside an airtight container to keep oxygen away from it. Like every other thing, solder paste also has an expiry date. It would be best if you don’t use it after the date has passed because it will lose its properties by then, and you won’t get a good result.

How To Use

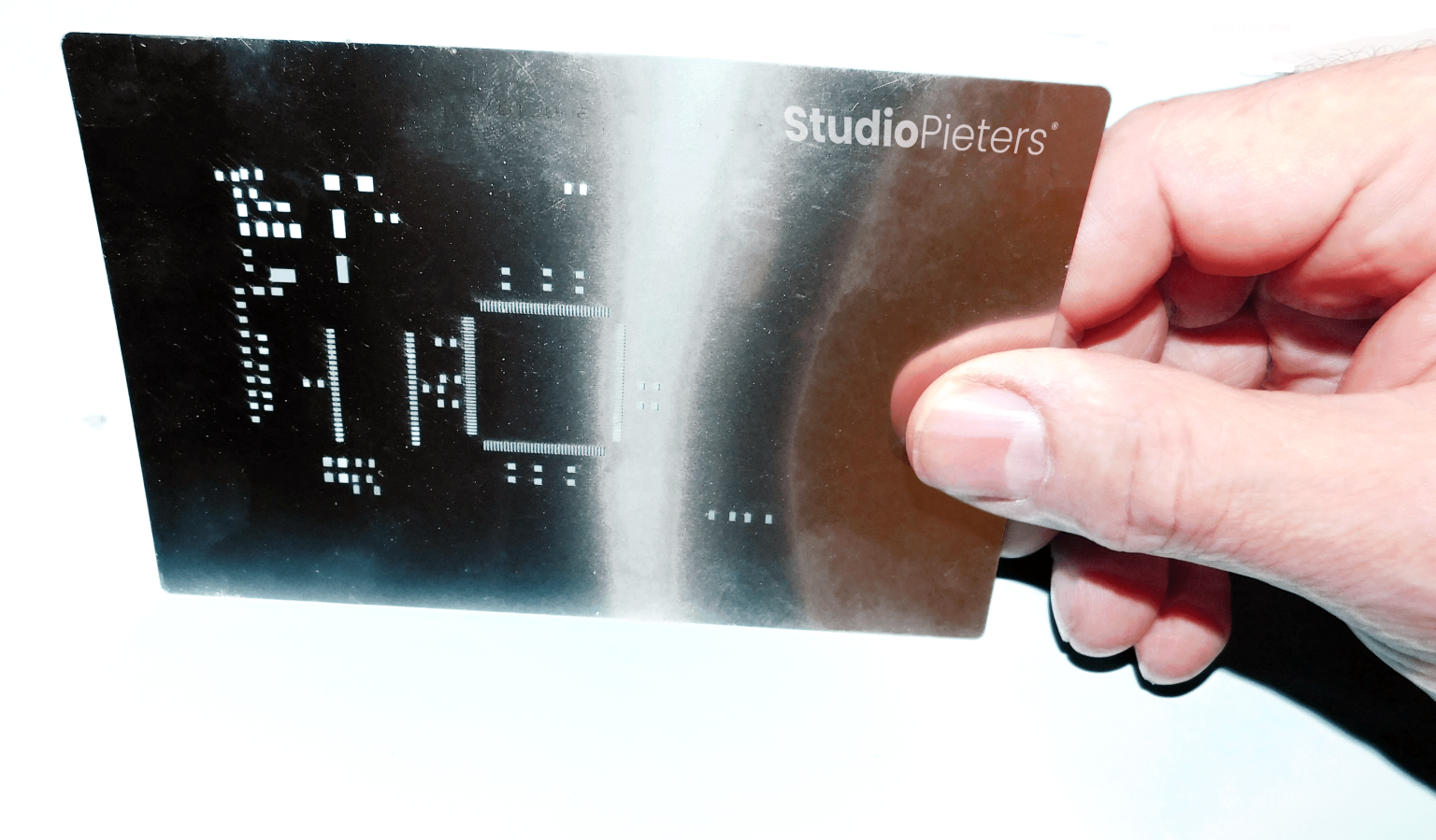

Here comes the real question – how do we use solder paste? The application of solder paste on the PCB is not an easy process. It requires great precision and accuracy. The paste is only applied to some areas and not the entire board. So, while applying it, you need to make sure that the application is exact. The process of applying the paste can be made easier by using an SMT stencil.

So, the first step is to create the right stencil according to your circuit. Seeedstudio manufactures the best SMT stencils that match your application. All you need to do is provide us with your circuit Gerber file and leave everything on us. The stencil makes sure that the solder paste is applied at specific locations in the right quantity. Using too much or too little paste will hinder the performance of your circuitry. Once you get your hands on the stencil, it is time to apply the paste.

We let the solder paste stand for a few hours, typically 4-5 hours, to make sure the paste is at a temperature (22 ℃ to 28 ℃) where it can be used easily. If you apply cold solder paste on your PCB, it won’t adhere to the surface, causing your components to fall off. But keep in mind that you can’t heat the paste to raise its temperature. It must undergo a gradual temperature change to keep it from deforming.

You need to apply the right amount of paste on the board. Too little will cause your components to fall off, while too much of it will cause the board to have uneven tracks, and the flow of current would get disturbed.

After applying the solder paste, the next stage is to place the components on the PCB. You need to pick and place the components and places them in the right position on the PCB. You can do this manually, but you need to be careful not to place the component wrongly or in the wrong place.

Moreover, be careful not to mishandle the PCB at this point because that might lead to your components falling off the board, and you certainly do not want that to happen. Note, It is recommended to let the board stay idle, so the paste can dry off and grip the components.

Conclusion

Solder paste is a very crucial part of the PCB assembly process. Without it, the entire process is incomplete because you won’t be able to mount your components on the board. It is also essential to choose the right type of solder paste, which exactly matches your application. Using the wrong type of solder paste will get you into trouble because your circuit board will not function correctly. It is best to get your solder paste applied by a professional.

Reference:

Electronicsnotes, What is Solder Paste & How to Use It, https://www.electronics-notes.com/articles/constructional_techniques/soldering/solder-paste-how-to-use.php Wikipedia, Solder paste, https://en.wikipedia.org/wiki/Solder_paste pcbonline, How to Choose, Store, and Use Solder Paste for Assembly, https://www.pcbonline.com/blog/solder-paste.html